We offer several models of onion peeling machines, the capacity is from 500kg/hr to 2,500 kg/hr.

Our onion peeling machines can peel any size and variety of onions.

All onion peeling machines adopt the pneumatic principle. The onions are fed by the automatic feeding belt into the peeling chamber and the onion skins will be blown off by the compressed air flow.

Each model has a high peeling rate, perfect peeling result, energy-saving, easy cleaning, and low maintenance.

- Small Capacity Automatic Onion Peeler Machine

The automatic onion peeler machine adopts pneumatic principle, it can automatically remove the onion skin by high-pressure air, without damage. The peeling rate can reached 95%.

| Model | YT-600 |

| Capacity | 500kg/h |

| Power | 0.2 kw |

| Voltage | 220v, 50Hz |

| Dimension | 1340*860*1500 mm |

| Weight | 160kg |

| Air pressure | 0.8-0.9Mpa |

| Air flux | 2.0 m³ /min |

| Air compressor power | 15kw/380v |

| Material | Stainless steel 304 |

| Note: It has to be equipped with an air compressor (prepared by the user). | |

Features of Small Automatic Onion Peeler Machine

- Conveyor Belt Automatic Onion Peeling Machine

Fully automatic conveyor belt type onion peeling machine is the high-yield industrial onion processing equipment. It can peel the onions of 60mm to 100mm diameter without cutting the root. The skin is removed by compressed air. It can peel the onions clean in any state at one time. This onion peeling machine has been widely used in the vegetable processing industry.

3 models are available: single-belt onion peeling machine YB-1, double-belt onion peeling machine YB-2, and three-belt onion peeling machine YB-3.

| Model | YT-1 |

| Type | Single belt |

| Voltage | 380v, 50Hz |

| Air pressure | ≥1.0MPa |

| Air flux | 2-3 m³ /min |

| Power | 1.52kw |

| Capacity | 500-700kg/hr |

| Weight | 280 kg |

| Dimension | 2.05*1.06*1.96m |

| Onion diameter | 60-100mm |

| Note: An air compressor will be needed to run the onion peeling machine. | |

| Model | YT-2 |

| Type | Double-belt |

| Voltage | 380v, 50Hz |

| Air pressure | ≥1.0MPa |

| Air flux | 4-5 m³ /min |

| Power | 1.52kw |

| Capacity | 1,000-1,500kg/hr |

| Weight | 320 kg |

| Dimension | 2.3*1.2*1.95m |

| Onion diameter | 60-100mm |

| Note: An air compressor will be needed to run the onion peeling machine. | |

| Model | YT-3 |

| Type | Three-belt |

| Voltage | 380v, 50Hz |

| Air pressure | ≥1.0MPa |

| Air flux | 5-6 m³ /min |

| Power | 1.52kw |

| Capacity | 2,000-2,500kg/hr |

| Weight | 380 kg |

| Dimension | 2.25*1.25*2.00m |

| Onion diameter | 60-100mm |

| Note: An air compressor will be needed to run the onion peeling machine. | |

Features of Conveyor Belt Automatic Onion Peeling Machine

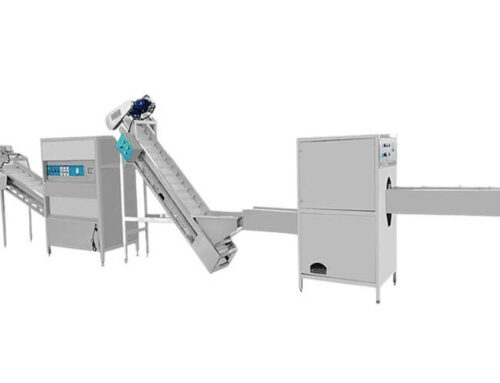

- Chain Type Continuous Onion Peeling Machine

Chain type onion peeling machine is powered by compressed air. It is equipped with automatic stainless steel chain-type conveyor to feed the onions into peeling chamber, which can realize continuous peeling. Onion skins are peeled off by the compressed air flow.

During the peeling process, the onions are completely peeled without friction, so the peeled onions are fresh, in good condition, and without damage and they can be stored for a long time.

| Model | YT-1000 |

| Power | 3kw, 380v |

| Capacity | 1,000-1,500kg/hr |

| Weight | 344 kg |

| Airflow | 45kw screw air compressor |

| Air pressure | 8kg/cm3 |

| Note: 1. The machine (such as size, capacity, etc.) can be customized as per your need.

2. Buyer needs to prepare the 45kw screw air compressor. When the machine working, the air compressor pressure needs to be 0.8Mpa. |

|