We design the garlic processing line based on your special garlic processing requirement. Here we just show a simple 600kg/hr and 1,000 kg/hr garlic processing lines for garlic separating & peeling. Other Garlic processing lines for making garlic paste, garlic powder, and dried garlic flakes are also available. Please contact us for your customized garlic processing line.

We can add the corresponding garlic grading machine, garlic paste grinding machine, garlic slicing machine, garlic drying machine and garlic powder grinding machine, garlic product packaging machine, etc. to the peeled garlic processing line, and design the whole processing project for you.

- Garlic Processing Line for Separating & Peeling

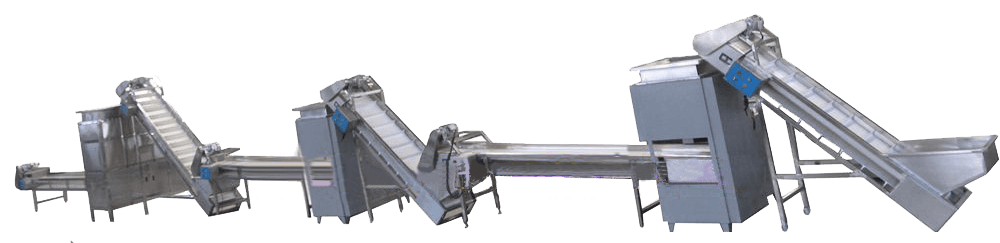

Garlic processing line for separating & peeling is mainly composed of elevator, garlic separating machine, garlic peeling machine, inspection conveyor for picking out unqualified garlic, etc.

Here are the details of 600kg/hr and 1,000 kg/hr peeled garlic processing lines.

600kg/hr Garlic Processing Line for Separating & Peeling

The 600kg/hr garlic processing line consists of elevator – garlic separating machine (primary separation)- conveying picking line – elevator – garlic separating machine (for secondary separation)-picking conveyor-elevator-garlic peeling machine- picking conveyor, etc.